Some of Martin Sala's Many Successes. . .

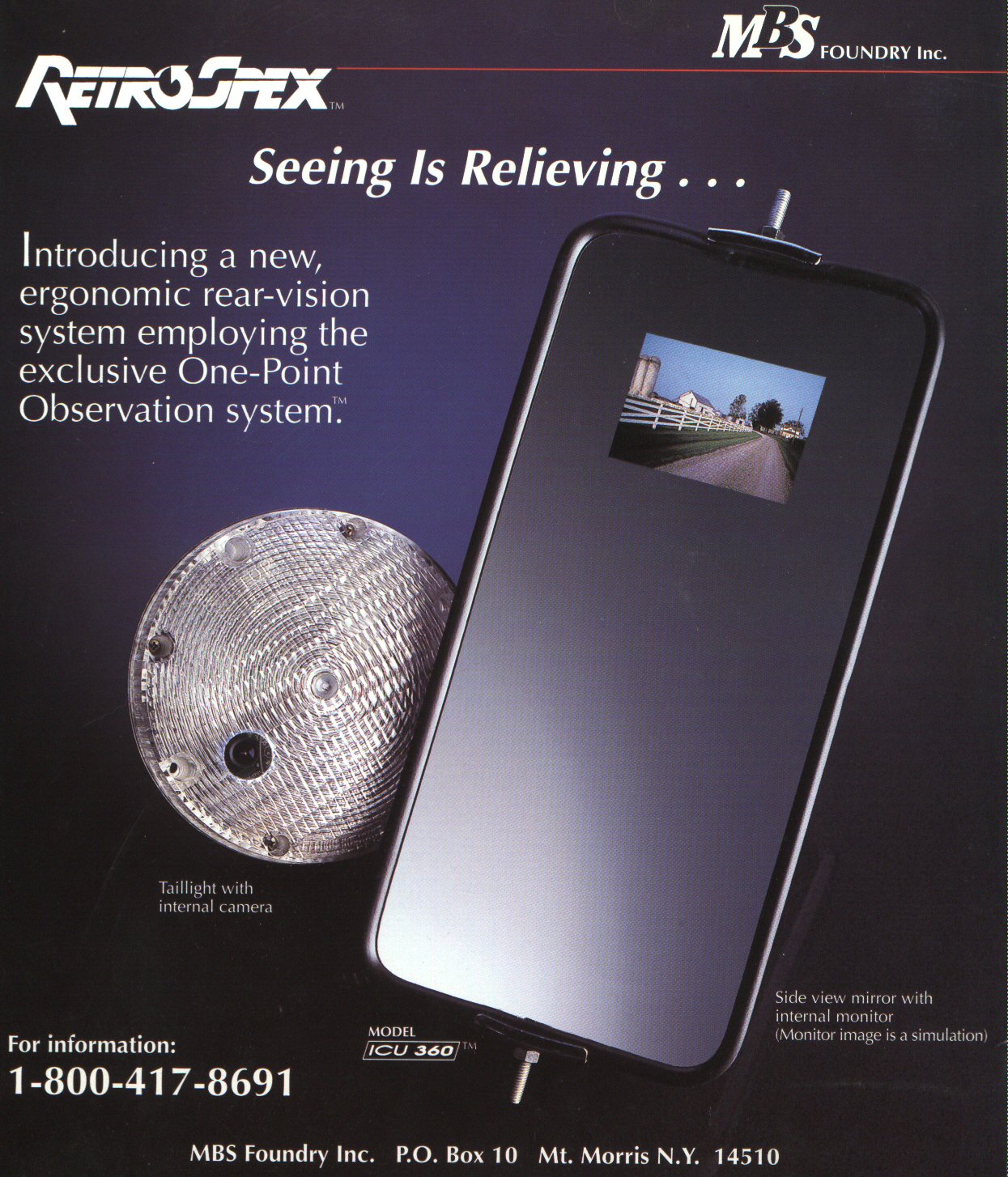

Martin Sala inverted the first rear-vision system for large vehicles in 1993; forming the MBS Foundry, Inc. in Mount Morris, NY to manufacture, sell and improve.

Shortly after joining Corning Incorporated in 1997 Martin was the Project Leader and an individual contributor that invented the instrumentation for Corning to deliver optically pristine High Purity Fused Silica (HPFS) to the National Ignition Facility at Lawrence Livermore. The LASER beam-path-optics that were made from this glass would not have been possible without Martin's contributions. For Martin's Star Trek Into Darkness connection>>>More click here.

Shortly after joining Corning Incorporated in 1997 Martin was the Project Leader and an individual contributor that invented the instrumentation for Corning to deliver optically pristine High Purity Fused Silica (HPFS) to the National Ignition Facility at Lawrence Livermore. The LASER beam-path-optics that were made from this glass would not have been possible without Martin's contributions. For Martin's Star Trek Into Darkness connection>>>More click here.

In 2008 Corning Incorporated faced the issue of infringement on its SMF-28 $2B fibre business. To solve this disastrous issue, Martin was one of three contributors that through nearly a year's worth of research, was able to improve the product and alleviate the IP issues. Additionally, Martin was able to invent a new apparatus for measuring the Coefficient of Friction of optical fiber on-the-draw.

In 2009, just before he was laid-off from Corning Incorporated as part of a financial restructuring, Martin invented an Electrostatic Catalytic Converter for use on any combustion engine that eliminates exhaust particulates, NOX substances and all Greenhouse gases. It is US Patent # 7959883.

More -

Founding the First Non-Destructive Analysis Lab at Corning Incorporated

Fractography was the only method available to view the inside of a failed device until Martin formed and operated Corning's first Non-Destructive Evaluation (NDE) lab which provided CAT-Scan, Ultrasound, X-ray, Con-focal Microscopy, SEM and fluorescence microscopy as standard fare. If the means (or modality) to see something wasn't available on-site, Martin found or invented.

Martin developed an on-line, real-time system for detecting a quality called shape during the production of 3 meter wide TFT glass drastically improving the quality of the product delivered.

Martin also supported all of the Corning Incorporated production facilities NDE needs that are located throughout the World.

Saving $3M loss/reservoir in Advanced Life-Sciences Genomics Printing

Corning Incorporated had developed an ingenious means of printing an array of 1,000 by 1,000 dots of DNA (each dot measuring 100u across) on a 1"x3" microscope slide. Part of Corning Life-Sciences, these DNA spots were used in drug-discovery. Once the DNA was loaded into the Pyrex print-reservoir (above) the $3M worth of material could not be removed should the reservoir prove faulty.

Using a combination of X-ray CT and Con-focal microscopy, Martin Sala developed a means was invented and deployed to production to analyze a reservoir before deployment and providing the necessary validation of the design. The channels that contained the DNA were 100u in diameter with 20u glass spacing. It took approximately 2 hours to collect the data from a 1" length of reservoir and three hours to process. All data crunching was performed in a DEC Alpha and Silicon Graphics O2 systems running Irix and VMS.

This work was done in conjunction with Dr. Rick Rogers of the Harvard School of Public Medicine.

Finding Subterranean Gas Leaks

Martin Sala is engaged in 2014 by a US-based robotics manufacturer to help develop a sensor-suite that locates imperfections of cast-iron natural gas mains and potentially preventing devastating or fatal leaks and subsequent explosions. This work is unique and may be transferable to any kind of pipe. This work has led to a working understanding of failure detection in gas mains, water mains and of Graphitic Corrosion. Because of intellectual property (IP) issues, the description of his work here must be limited. See CISBOT for some further details.

Detecting Hazardous or Explosive Gasses

Martin has designed equipment that will detect explosive gasses, such as Methane or Natural Gas, Hydrogen, Propane, at a distance to allow workers to enter a confined space knowing hazard level and being able to act accordingly.

Managed High-Tech Biomedical Engineering Department at Samaritan Medical Center

After taking over in September 2011, JACHO performed its once-every-three-year inspection for facility accreditation in November and out of all the Hospital's departments, Biomedical Engineering was the only one to be told, "Biomed is the only department doing it right; the only department that bases its actions upon hard-data!" When I assumed command, all policy and procedure manuals were out-of-date, budgets were nonresistant and any flow of accountability was missing.

Eliminated Platinum Loss in Diesel Particulate Filters (DPF) saving $1,000s/ Filter Loss

Designed means to evaluate micro-reactors for small-scale chemical processing plants

Nano-particle Semiconductors; Invented means to manufacture in an atmosphere - 5 US Patents